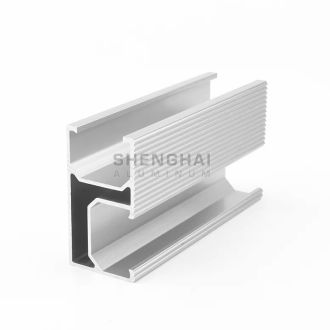

Aluminum L shape Corner For Solar Panel PV Mounting Bracket

Color:

Sliver Anodizing or Customized

OEM:

Available

Free Samples:

About 1 days can be sent

Supply Ability:

1200-1600 tons per month

Payment:

T/T, L/C

Product Origin:

Foshan China

Shipping Port:

Shenzhen/Guangzhou/Foshan

Lead Time:

7-15 Days

Product Description

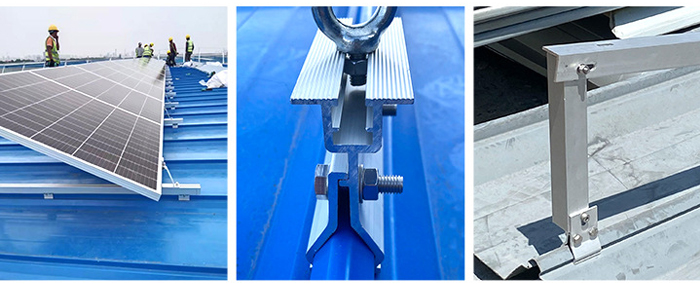

The aluminum L-shaped solar PV bracket corner code mainly plays an auxiliary role as the bracket and is used to install and fix the battery panels. Usually solar corner codes are used to connect solar panels and brackets. For some double-glass frameless modules, the corner code directly clamps the photovoltaic glass and then connects the bracket. The material of the solar corner code is generally 6063 aluminum alloy, and the surface is anodized. In addition to L shape photovoltaic corner codes, there are T shape, solar clamps, support corner codes, adjustable corner codes, etc. Shenghai Aluminum can provide you with all aluminum profiles and accessories for solar photovoltaics, and we will produce them for you, saving you more cost and time.

PV Solar Panel Aluminum L Shape Corner Size

40mm x 40mm x 3mm,

50mm x 50mm x 5mm,

30mm x 30mm x 2mm,

60mm x 60mm x 6mm, or customized.

Product Feature:

Advantage of aluminum rail solar panel

1. Corrosion resistance and strong oxidation resistance;

2. Strong strength and firmness;

3. Strong tensile strength;

4. High elasticity, rigidity and metal fatigue value;

5. Convenient transportation and installation, even if the surface is scratched, it will not oxidize, and does not affect performance;

6. It can adapt to various environments through convenient selection of different materials;

7. The service life is more than 25 years.

Our Factory

Product Application

Packaging Details

PE film for each profile/ Shrink PE film for each bundle, Slot packing, Craft paper/ Foam Paper/Carton box Product Detail

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

Table of Chemical Composition of Aluminum Alloy

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |

Leave a Message