Aluminum Solar Panel Frame Manufacturer

|

|

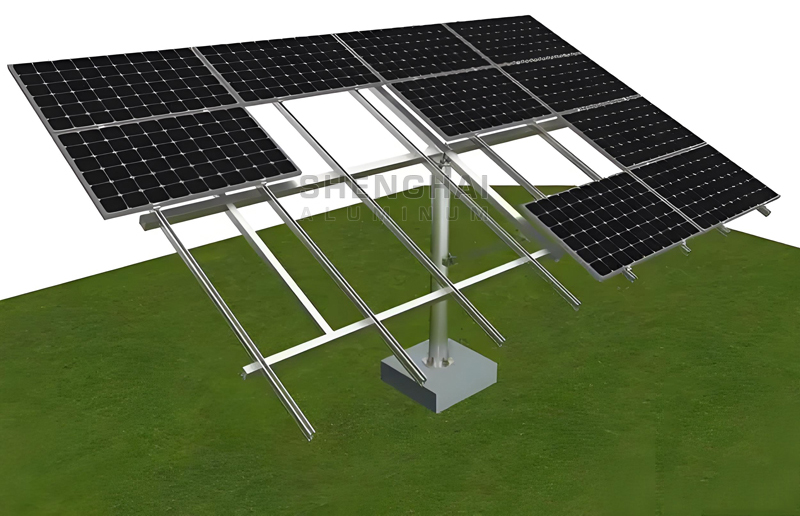

As a key component of photovoltaic solar module assembly, aluminum solar panel frame provides structural stability for the overall combination of glass, EVA encapsulation, battery and backplane, while enhancing the strong support of the component and extending the service life of the battery.

Shenghai Aluminum has been committed to the solar panel extrusion profile industry for 13+ years. We provide aluminum solar panel frames, aluminum solar mounting brackets, and solar aluminum accessories (clamps, corners, etc.) for solar PV. We have a professional team of solar engineers, and you can trust us to provide the best solutions for your solar photovoltaic system project with professional knowledge and rich experience.

Aluminum profiles have more advantages than other materials, so more and more solar projects use aluminum. Shenghai Aluminum extruded profiles are more popular in the application of solar panels, and they play an important role in customers' solar projects. If you want more about solar aluminum profiles, please contact us for a quote or product details.

Our Aluminum Solar Panel Case Show

Is the aluminum solar panel frame important?

The frame of the solar panel is used to fix and support the solar panel. Why are the frames made of aluminum? Is the aluminum solar panel frame really important?1. Using an aluminum alloy frame can protect the solar panels.

2. The aluminum frame has good electrical conductivity and can play a role in lightning protection in thunderstorms.

3. The aluminum frame has high strength, is stable and not easy to fade, and is corrosion-resistant and UV-resistant.

4. Anodized aluminum alloy 6063 has high corrosion resistance and oxidation resistance.

5. It has high tensile strength and can withstand severe weather (for example, snow, rain, storm, etc.).

How many types of aluminum solar panels are there?

Currently, there are four main types of aluminum solar panels in the solar industry.Monocrystalline silicon solar panels

Polycrystalline silicon solar panels

Thin-film solar panels

Double-glass solar panels

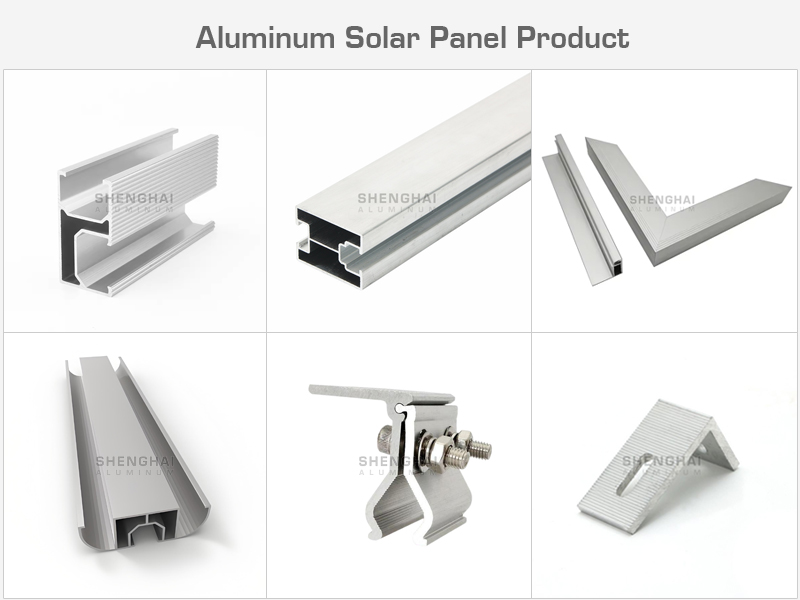

What aluminum profiles are used in solar panels?

Solar panels use a variety of aluminum profiles during installation and use, each with specific functions and features.Aluminum solar panel frame

Aluminum bracket profile

Aluminum mounting track profile

Aluminum components

Aluminum fixtures

Aluminum end caps

Aluminum corner guards

Which aluminum alloy is suitable for solar panel frame

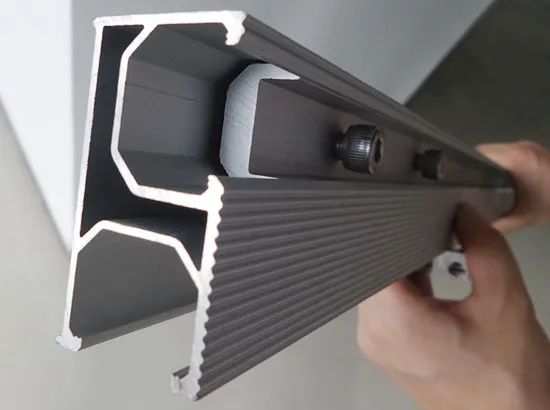

The aluminum alloy used for solar panel frames is mainly 6061 or 6063. These two aluminum alloy grades have good corrosion resistance, high tensile strength and machinability. Moreover, they are lightweight, easy to transport, install, and can save a lot of money.What surface treatments are there for aluminum frames of solar panels?

Because photovoltaic modules' outdoor service life is about 25 years, the aluminum frames used in them must be highly resistant to oxidation and corrosion. The frames used in general aluminum solar panels are divided into three types: anodized, sandblasting anodized , and electrophoretic anodized.Anodizing: After anodizing, aluminum alloy will form a dense oxide film on its surface. It also changes the surface state and properties of aluminum profiles, such as surface coloring, improving corrosion resistance, enhancing wear resistance and hardness, and protecting the surface of aluminum profiles.

Sandblasting anodized: Generally, after sandblasting, all the oxides on the surface are processed. After impact, the surface metal is pressed into a dense arrangement, and the aluminum alloy crystals become smaller. The hardness is increased, which is relatively firm and dense.

Electrophoretic anodized: Electroplating can enhance the corrosion resistance of aluminum alloy (the coating metal is corrosion-resistant mainly metal), increase hardness, prevent wear, lubricity, heat resistance and surface beauty.

According to customer experience, the most practical and popular surface treatments are sandblasting, silver anodizing, and black anodizing. These treatments not only protect solar panels and components but also prevent aluminum profiles from being scratched.

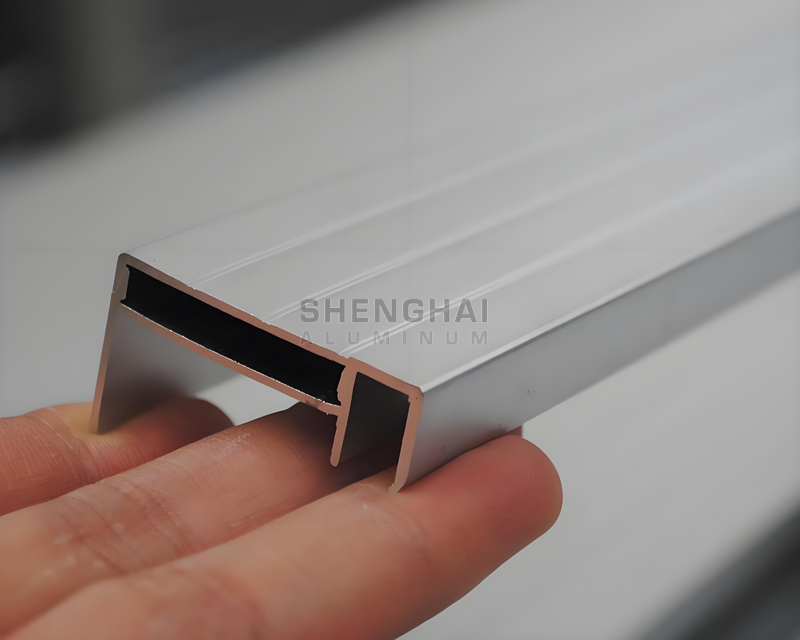

What sizes are available for aluminum solar panel frames? Can they be customized?

Standard aluminum solar panel frames are available in a variety of sizes. Common aluminum frame sizes include:25 mm × 25 mm

25 mm × 30 mm

30 mm × 35 mm

35 mm × 35 mm

35 mm × 40 mm

35 mm × 50 mm

Or customized

In addition to these standard sizes, Shenghai Aluminum supports customized production of solar panel frames, including drawing design and mold making, and then extrusion and surface treatment.

Professional and Trustworthy Aluminum Solar Panel Frame Supplier - Shenghai Aluminum

As a solar photovoltaic company, choosing a professional and trustworthy supplier is very important. Shenghai Aluminum leads the development of the aluminum solar industry with professional technology and high quality. We have 13+ years of aluminum solar experience and a professional team and advanced production equipment to produce high-quality solar panel aluminum frames, aluminum mounting brackets aluminum accessories, etc.We use high-quality 6063 and 6061 aluminum alloys to ensure that the frame has excellent strength, durability and corrosion resistance, meeting the high standards of solar outdoor use for more than 25 years. The most advanced anodizing surface treatment process ensures that the aluminum profile frame can adapt to various harsh environments. We strictly control every link of production, from raw materials to finished products, and every step is strictly inspected to ensure that the product quality meets international standards. Quality inspectors carefully inspect every profile material to ensure every profile is perfect.

Choose Shenghai Aluminum to save money, time, and energy on your solar photovoltaic project. Our aluminum frame will be the best part of your solar panel.