Premium Curtain Wall Solutions with Safety & Reliability First

China has become the world's largest curtain wall market, and Shenghai Aluminum has always been based on professionalism and integrity, and is committed to providing customers with safe and reliable products and services. We are well aware that there are some bad companies in the market that use inferior products and water-based paint to impersonate fluorocarbon paint. This behavior not only harms the interests of customers, but also poses a potential threat to building safety. Shenghai firmly opposes this dishonest practice and always puts safety first. Therefore, we will take the initiative to provide detailed information such as the composition, specifications, and processing technology of the materials, so that customers can know every detail of the product. Shenghai Aluminum, with professional technology, professional after-sales, high-quality products and honest attitude, provides customers with safe and reliable choices, making your building not only beautiful and durable, but also safer and more reliable. After the spraying process, the curtain wall of our Shenghai Aluminum has a service life of 10-15 years under the sun, and a single curtain wall can be up to 12.5 meters long! While focusing on safety and practicality, it also does not lose its beauty. In terms of materials, it is mainly made of high-quality aluminum alloy materials of the 6063-T5 and T6 series, which can achieve high toughness! High corrosion resistance! Even humid or corrosive environments can adapt. In addition, it can greatly reduce the overall weight of the building. Bring a more economical choice for your project. Whether it is a high-rise building or a home cottage, or a hospital swimming pool, school or garden, our Shenghai curtain wall can create a safe, beautiful and practical appearance for you.

If you have plans to build curtain walls recently, Shenghai Aluminum will be your best choice.

Our Curtain Wall Systems Feature:

- Wind Pressure Resistance: Remains stable under strong wind conditions.

- Water Tightness: Effectively prevents rainwater infiltration.

- Air Tightness: Superior air-sealing performance.

- In-Plane Deformation Adaptability: Accommodates minor structural movements.

- Thermal Performance: Excellent insulation and heat retention.

- Sound Insulation: Provides effective noise reduction.

- Impact Resistance: Strong resistance to external impacts.

- Optical Performance: Outstanding light transmission.

- Load-Bearing Capacity: Solid structure with high load-bearing strength.

Our Product Application Scenarios:

- Commercial Curtain Walls

- Residential Curtain Walls

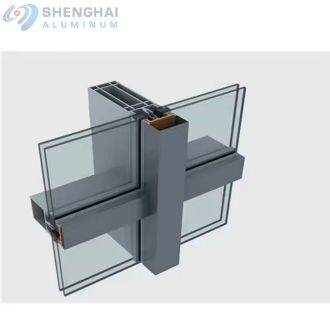

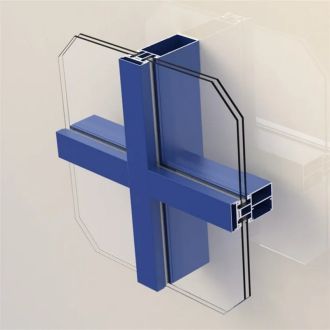

- Unitized Curtain Wall Systems

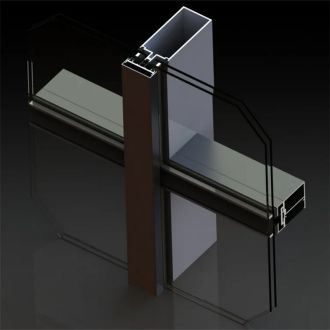

- Stick Curtain Wall Systems

- Glass Facade Solutions

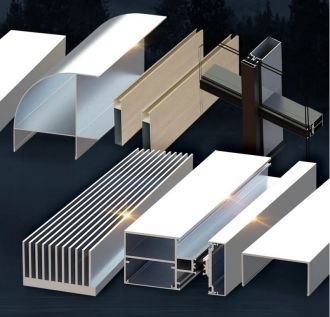

- Aluminum Curtain Wall Profiles

- High-Performance Thermal Curtain Walls

Application Scenario

| Material & Temper | Alloy 6063-T5,6061-T6 , We will never use aluminum scrap. |

| Surface Treament | Mill-Finished, Anodizing, Powder Coating, Electrophoresis, Wood Grain, Polishing, Brushing, etc. |

| Colour | Silver, Champage, Bronze, Golden, Black, Sand coating, Anodized Acid and alkali or Customized. |

| Film Standard | Anodized:7-23 μ , Powder coating: 60-120 μ , Electrophoresis film: 12-25 μ. |

| Lifetime | Anodized for 12-15 years outdoor, Powder coating for 18-20 years outdoor. |

| MOQ | 500 kgs. Usually 10-12 tons for a 20'FT; 20-23 tons for a 40HQ. |

| Length | 5.8M or Customized. |

| Thickness | 0.4mm-20mm or Customized. |

| Application | Building and Construction and Decoration. |

| Extrusion Machine | 600-3600 tons all together 6 extrusion lines. |

| Capability | Output 1200 tons per month. |

| Profile type |

1. Sliding window and door profiles; 2. Casement window and door profiles; 3. Aluminum profiles for LED light; 4. Tile Trim Aluminum profiles; 5. Curtain wall profile; 6. Aluminum heating insulation profiles; 7. Round/Square General profiles; 8. Aluminum heat sink; 9. Others Industry profiles. |

| New Moulds | Opening new mould about 7-10 days, absolutely moulds cost can be refund. |

| Free Samples | Can be available all the time, about 1 days can be sent. |

| Fabrication | Die designing→ Die making→ Smelting & alloying→ QC→ Extruding→ Cutting→ Heat Treatment→ QC→ Surface treatment→ QC→ Packing→ QC→ Shipping→ After Sale Service |

| Deep Processing | CNC / Cutting / Punching / Checking / Tapping / Drilling / Milling |

| Certification |

1. ISO9001-2008/ISO 9001:2008; 2. GB/T28001-2001(including all the standard of OHSAS18001:1999); 3. GB/T24001-2004/ISO 14001:2004; 4. GMC. |

| Payment |

1. T/T: 30% deposite, the balance will be paid before delivery; 2. L/C: the balance irrevocable L/C at sight. |

| Delivery time |

1. 15 days production ; 2. If opening mould, plus 7-10 days. |

| OEM | Available. |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Impurity | Al | |

| Unit | Total | ||||||||||

| 6063 | 0.2-0.6 | <0.35 | <0.1 | <0.1 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | <0.15 | 0.8-1.2 | 0.04-0.35 | <0.25 | <0.15 | <0.05 | <0.15 | Surplus |

| 6005 | 0.6-0.9 | <0.35 | <0.1 | <0.1 | 0.4-0.9 | 0.1 | <0.1 | <0.1 | <0.05 | <0.15 | Surplus |

| 6060 | 0.3-0.6 | 0.35-0.6 | 0.1-0.3 | <0.1 | <0.1 | <0.15 | <0.05 | <0.1 | <0.05 | <0.15 | Surplus |