Why Choose Anodizing For Aluminum Alloy

Updated: 6 Aug 2024

We all know that aluminum alloy will form a dense oxide film on the surface, making the surface of aluminum alloy profiles more corrosion-resistant and wear-resistant. However, the profiles need to be surface treated for different applications of aluminum profiles. Therefore, most aluminum profiles used as construction and industrial materials will be anodized. Why choose anodizing for aluminum alloy? Shenghai Aluminum lists the following reasons for you:

Anodizing, electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products (anodes) under the action of an applied current in the corresponding electrolyte and specific process conditions.

Improve corrosion resistance

Improve corrosion resistance

Aluminum alloy is a corrosion-resistant metal. Because aluminum is very active, it is easy to react chemically with oxygen in the air to form aluminum oxide, isolating the air and preventing the aluminum matrix from oxidizing. However, the naturally generated oxide film plays an antioxidant role. Why is anodizing still needed? The reason is that.

1.The naturally formed oxide film is uneven, causing the color of the aluminum alloy surface to be different in depth and ugly;

2.The naturally formed oxide film is very thin, easy to scratch, and has weak corrosion resistance. The artificial oxide film generated by anodizing is uniform, dense, and more corrosion-resistant. Metal or alloy parts are used as anodes, and an oxide film is formed on the surface by electrolysis.

Improve wear resistance

Because aluminum alloy's hardness is much lower than that of steel, it is scratched and worn by special processes. However, the surface of industrial aluminum profiles that have been anodized is very hard, and the oxide film has a high hardness. Therefore, they are very wear-resistant and not easy to scratch after anodizing.

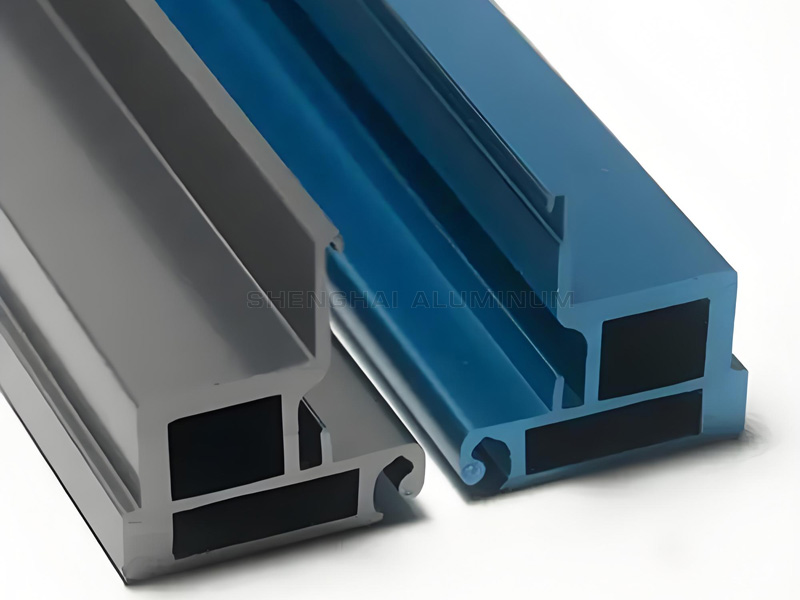

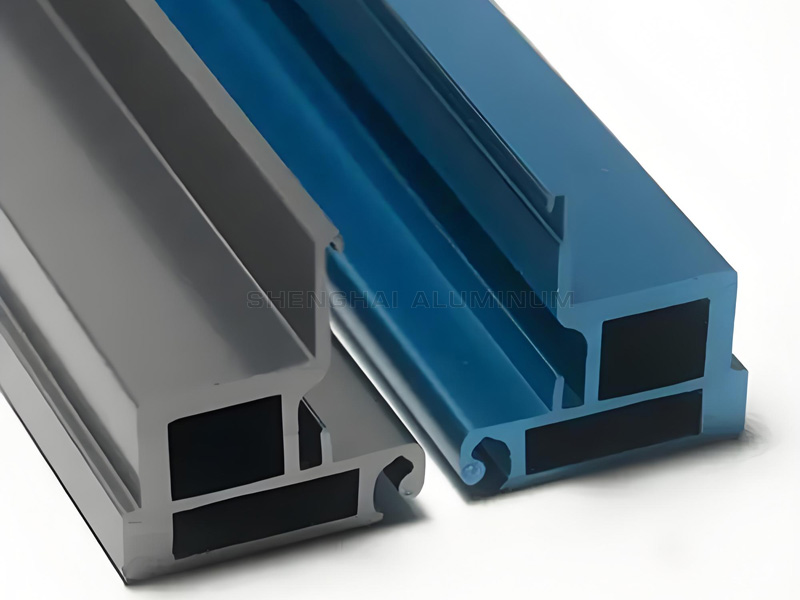

Surface coloring of decorative aluminum products

Surface coloring of decorative aluminum products

After anodizing, a protective film will form on the surface of the aluminum profile, and this protective film has high transparency. If dyes of other colors are added, a colored oxide film will be formed. It has good decorative and anti-corrosion properties and can achieve the same effect as tiles.

Improve insulation

The oxide film obtained after anodizing aluminum and aluminum alloy products has a high resistance, so it improves the electrical insulation of certain products. After processing, it also improves the bonding strength with organic coatings and inorganic covering layers.

Primer for spray painting

Some aluminum parts need to be sprayed on the surface. The surface gaps of anodized aluminum parts have strong adsorption, making the spray painting more uniform and beautiful.

In general, anodizing technology makes aluminum profiles easier to process and more weather-resistant. It also widens the application range of aluminum profiles and makes them adaptable to various environments.

Anodizing, electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products (anodes) under the action of an applied current in the corresponding electrolyte and specific process conditions.

Aluminum alloy is a corrosion-resistant metal. Because aluminum is very active, it is easy to react chemically with oxygen in the air to form aluminum oxide, isolating the air and preventing the aluminum matrix from oxidizing. However, the naturally generated oxide film plays an antioxidant role. Why is anodizing still needed? The reason is that.

1.The naturally formed oxide film is uneven, causing the color of the aluminum alloy surface to be different in depth and ugly;

2.The naturally formed oxide film is very thin, easy to scratch, and has weak corrosion resistance. The artificial oxide film generated by anodizing is uniform, dense, and more corrosion-resistant. Metal or alloy parts are used as anodes, and an oxide film is formed on the surface by electrolysis.

Improve wear resistance

Because aluminum alloy's hardness is much lower than that of steel, it is scratched and worn by special processes. However, the surface of industrial aluminum profiles that have been anodized is very hard, and the oxide film has a high hardness. Therefore, they are very wear-resistant and not easy to scratch after anodizing.

After anodizing, a protective film will form on the surface of the aluminum profile, and this protective film has high transparency. If dyes of other colors are added, a colored oxide film will be formed. It has good decorative and anti-corrosion properties and can achieve the same effect as tiles.

Improve insulation

The oxide film obtained after anodizing aluminum and aluminum alloy products has a high resistance, so it improves the electrical insulation of certain products. After processing, it also improves the bonding strength with organic coatings and inorganic covering layers.

Primer for spray painting

Some aluminum parts need to be sprayed on the surface. The surface gaps of anodized aluminum parts have strong adsorption, making the spray painting more uniform and beautiful.

In general, anodizing technology makes aluminum profiles easier to process and more weather-resistant. It also widens the application range of aluminum profiles and makes them adaptable to various environments.