What Is Heat Sink Aluminum Profile

Updated: 23 Oct 2024

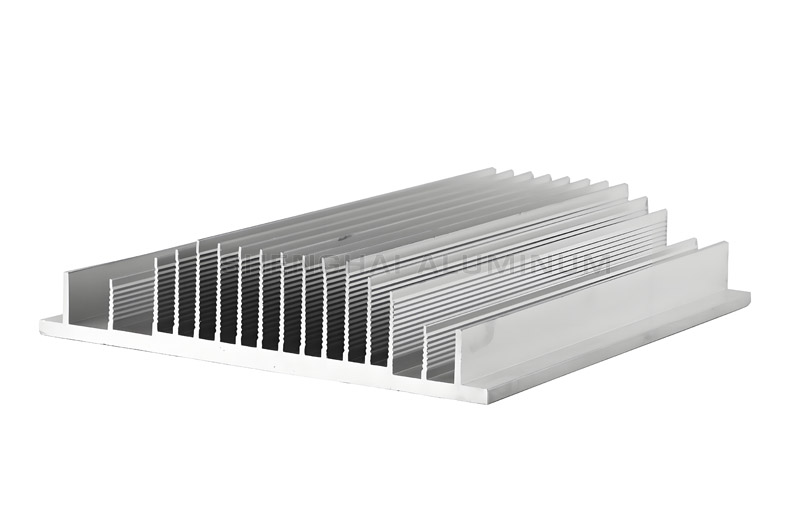

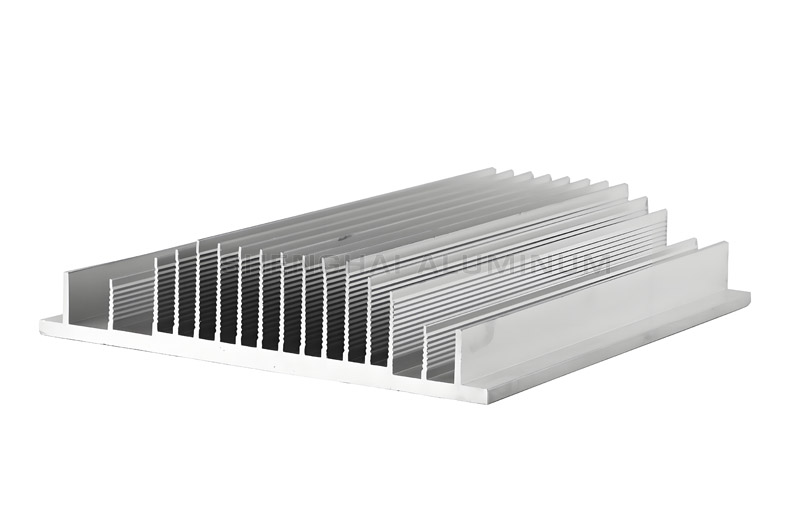

In industrial and electronic products, heat sink is a key factor in ensuring the regular operation of equipment and extending its service life. As an efficient heat dissipation solution, radiator aluminum profiles are widely used in modern industry due to their excellent thermal conductivity and lightness. This article will give you an in-depth understanding of heat sink aluminum profiles.

Types of heat sink aluminum profiles

Types of heat sink aluminum profiles

According to their structure and application scenarios, heat sink aluminum profiles are mainly divided into the following categories:

Extruded heat sink: formed by aluminum extrusion, with different cross-sectional shapes.

Casting radiator: made by aluminum casting process, suitable for radiators with complex shapes.

Composite radiator: combines processes such as extrusion and casting to meet special heat dissipation needs.

Difficulties in making heat sink aluminum profiles

The production of aluminum heatsink profiles faces the following difficulties:

Precision extrusion: The profile must be precisely sized and shaped, and the extrusion process is extremely demanding.

Heat treatment: To improve strength and hardness, appropriate heat treatment is required, but improper treatment may affect thermal conductivity.

Surface treatment: To improve corrosion resistance and aesthetics, surface treatment such as anodizing is required.

Production standards for heat sink aluminum profiles

Production standards for heat sink aluminum profiles

According to industry standards, the production of aluminum heat sink profiles should meet the following conditions:

Material standards: High-purity aluminum alloys, such as 6063 aluminum alloy, are usually used.

Dimensional accuracy: The dimensional tolerance of the profile must be controlled within ±0.1mm.

Surface quality: No defects such as bubbles, cracks, oxidation, etc.

Scope of use of aluminum heat sink profiles

Heat sink aluminum profiles are widely used in the following fields:

Electronic industry: used for heat dissipation of electronic components such as CPU and GPU.

Automotive industry: used for heat dissipation of components such as engines and gearboxes.

Industrial equipment: used for heat dissipation of equipment in industries such as power electronics and mechanical manufacturing.

Aluminum heat sink profiles have become a special product among industrial aluminum profiles due to their high production difficulty and high industry threshold. They require materials with excellent thermal conductivity and exquisite manufacturing processes to meet the heat dissipation needs of different application scenarios.

Aluminum heat sink profiles have become a special product among industrial aluminum profiles due to their high production difficulty and high industry threshold. They require materials with excellent thermal conductivity and exquisite manufacturing processes to meet the heat dissipation needs of different application scenarios.

Understanding the types, production difficulties, production standards and scope of use of aluminum heat sink profiles can help us make more informed decisions when choosing radiators. With the development of technology and industry progress, heatsink aluminum profiles will continue to play an important role in heat dissipation solutions.

According to their structure and application scenarios, heat sink aluminum profiles are mainly divided into the following categories:

Extruded heat sink: formed by aluminum extrusion, with different cross-sectional shapes.

Casting radiator: made by aluminum casting process, suitable for radiators with complex shapes.

Composite radiator: combines processes such as extrusion and casting to meet special heat dissipation needs.

Difficulties in making heat sink aluminum profiles

The production of aluminum heatsink profiles faces the following difficulties:

Precision extrusion: The profile must be precisely sized and shaped, and the extrusion process is extremely demanding.

Heat treatment: To improve strength and hardness, appropriate heat treatment is required, but improper treatment may affect thermal conductivity.

Surface treatment: To improve corrosion resistance and aesthetics, surface treatment such as anodizing is required.

According to industry standards, the production of aluminum heat sink profiles should meet the following conditions:

Material standards: High-purity aluminum alloys, such as 6063 aluminum alloy, are usually used.

Dimensional accuracy: The dimensional tolerance of the profile must be controlled within ±0.1mm.

Surface quality: No defects such as bubbles, cracks, oxidation, etc.

Scope of use of aluminum heat sink profiles

Heat sink aluminum profiles are widely used in the following fields:

Electronic industry: used for heat dissipation of electronic components such as CPU and GPU.

Automotive industry: used for heat dissipation of components such as engines and gearboxes.

Industrial equipment: used for heat dissipation of equipment in industries such as power electronics and mechanical manufacturing.

Understanding the types, production difficulties, production standards and scope of use of aluminum heat sink profiles can help us make more informed decisions when choosing radiators. With the development of technology and industry progress, heatsink aluminum profiles will continue to play an important role in heat dissipation solutions.