What Are Surface Treatments For Aluminum Profiles

Updated: 18 Jul 2024

Aluminum has the advantages of low density, good electrical conductivity, and easy recycling. Its high plasticity allows it to be made into various products through pressure processing methods such as extrusion and stretching. Under natural conditions or anodizing, a protective oxide film will form on the surface of aluminum, which has better corrosion resistance than steel. Through surface treatment, the surface properties of aluminum can be further improved or changed.

There are many ways to treat the surface of aluminum profiles, mainly including: sandblasting (forming a matte pearl silver surface), polishing (forming a mirror effect), brushing (forming a satin effect), electroplating (covering a layer of other metals), and spraying (covering other non-metallic coatings).

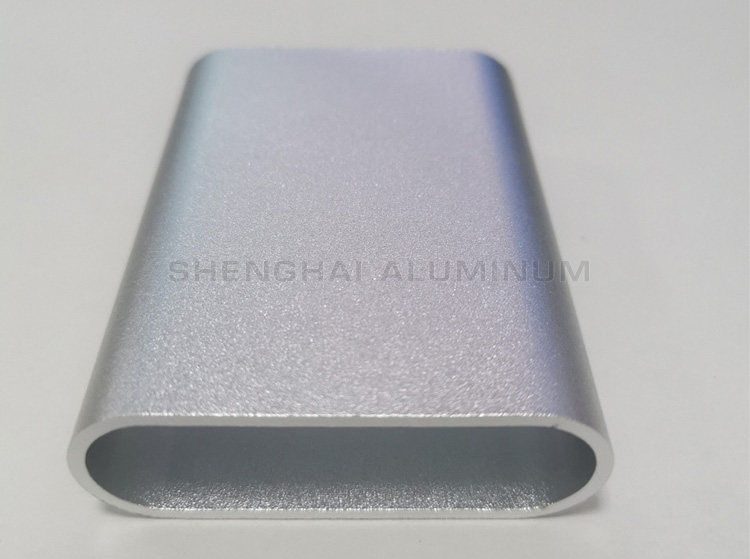

Sandblasting

Sandblasting uses compressed air as a power source to spray materials (such as copper ore sand, quartz sand, corundum, iron sand, and sea sand) at high speed onto the surface of the workpiece to be processed through a high-speed jet beam to change its appearance or shape. This process is widely used in engineering and surface treatment, such as increasing the viscosity of bonded parts, removing dirt, optimizing surface burrs after machining, and matte surface treatment. Sandblasting is more uniform and efficient than manual polishing, giving the product a low-key and durable characteristic.

Polishing

Polishing processes are mainly divided into mechanical, chemical, and electrolytic polishing. After mechanical polishing and electrolytic polishing, the surface effect of aluminum parts can be close to that of stainless steel mirrors, presenting a high-end, simple, fashionable and futuristic feeling.

Brushing

Metal brushed is a manufacturing process in which sandpaper is repeatedly used to scrape out the lines of aluminum plates. It can be divided into straight wire drawing, random wire drawing, spiral brushing, and thread brushing. Fine silk marks are clearly visible through the metal brushing process, making the metal surface glow with fine hair luster in matte, giving the product a sense of fashion and technology.

Highlight cutting

Highlight cutting

Highlight cutting uses a precision engraving machine to reinforce the diamond knife on the high-speed rotating (generally 20,000 rpm) precision engraving machine spindle for cutting, producing local highlight areas on the product's surface. The brightness of the cutting highlight is affected by the speed of the milling drill bit. The faster the drill bit speed, the brighter the cutting highlight; the slower the speed, the darker the cutting highlight and the easier it is to produce knife marks. High gloss cutting is widely used on the metal frames of mobile phones (such as iPhone 5) and some high-end TVs. Combined with anodizing and wire drawing processes, it gives the product a sense of fashion and technological sharpness.

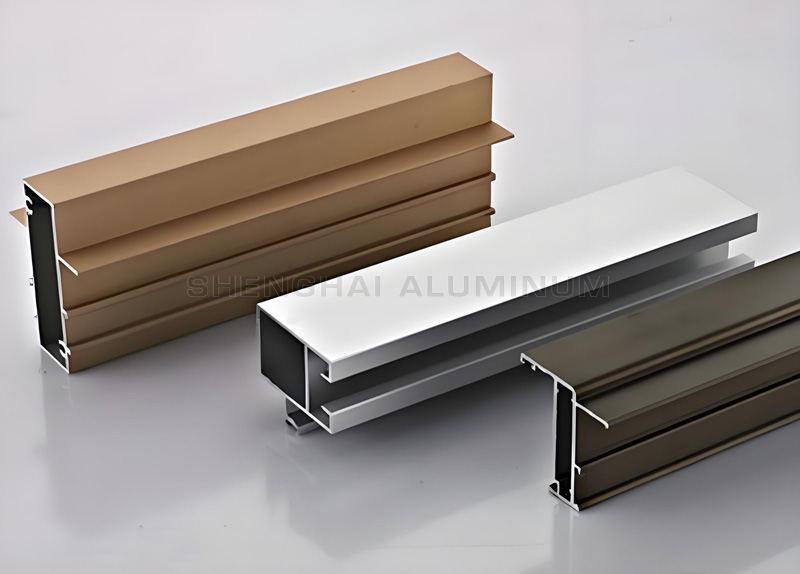

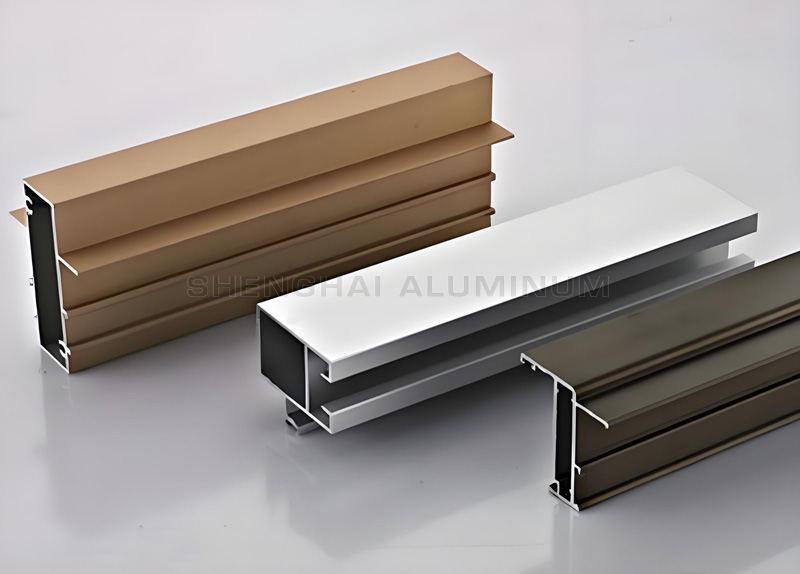

Anodizing

Anodizing refers to the process of forming an oxide film on the surface of aluminum and its alloys through electrochemical oxidation. This process is carried out by applying an external current to the aluminum product (anode) under specific electrolyte and process conditions. Anodizing not only solves the defects of aluminum surface hardness and wear resistance, but also prolongs the service life of aluminum and enhances its aesthetics. It has become an indispensable part of aluminum surface treatment and is currently the most widely used and successful process.

Two-color anodizing

Two-color anodizing

Two-color anodizing involves anodizing a product and giving different colors to specific areas. Although the process is complex and the cost is high, the two-color contrast can better reflect the product's high-end and unique appearance.

In general, aluminum profiles' processing performance is better than that of other materials, which allows them to meet the current market's customization needs and produce a variety of aluminum profile products. In addition, the surface treatment process of aluminum profiles is very rich, which greatly meets people's needs for construction and home decoration, making them widely used and deeply loved by the public.

There are many ways to treat the surface of aluminum profiles, mainly including: sandblasting (forming a matte pearl silver surface), polishing (forming a mirror effect), brushing (forming a satin effect), electroplating (covering a layer of other metals), and spraying (covering other non-metallic coatings).

Sandblasting

Sandblasting uses compressed air as a power source to spray materials (such as copper ore sand, quartz sand, corundum, iron sand, and sea sand) at high speed onto the surface of the workpiece to be processed through a high-speed jet beam to change its appearance or shape. This process is widely used in engineering and surface treatment, such as increasing the viscosity of bonded parts, removing dirt, optimizing surface burrs after machining, and matte surface treatment. Sandblasting is more uniform and efficient than manual polishing, giving the product a low-key and durable characteristic.

Polishing

Polishing processes are mainly divided into mechanical, chemical, and electrolytic polishing. After mechanical polishing and electrolytic polishing, the surface effect of aluminum parts can be close to that of stainless steel mirrors, presenting a high-end, simple, fashionable and futuristic feeling.

Brushing

Metal brushed is a manufacturing process in which sandpaper is repeatedly used to scrape out the lines of aluminum plates. It can be divided into straight wire drawing, random wire drawing, spiral brushing, and thread brushing. Fine silk marks are clearly visible through the metal brushing process, making the metal surface glow with fine hair luster in matte, giving the product a sense of fashion and technology.

Highlight cutting uses a precision engraving machine to reinforce the diamond knife on the high-speed rotating (generally 20,000 rpm) precision engraving machine spindle for cutting, producing local highlight areas on the product's surface. The brightness of the cutting highlight is affected by the speed of the milling drill bit. The faster the drill bit speed, the brighter the cutting highlight; the slower the speed, the darker the cutting highlight and the easier it is to produce knife marks. High gloss cutting is widely used on the metal frames of mobile phones (such as iPhone 5) and some high-end TVs. Combined with anodizing and wire drawing processes, it gives the product a sense of fashion and technological sharpness.

Anodizing

Anodizing refers to the process of forming an oxide film on the surface of aluminum and its alloys through electrochemical oxidation. This process is carried out by applying an external current to the aluminum product (anode) under specific electrolyte and process conditions. Anodizing not only solves the defects of aluminum surface hardness and wear resistance, but also prolongs the service life of aluminum and enhances its aesthetics. It has become an indispensable part of aluminum surface treatment and is currently the most widely used and successful process.

Two-color anodizing involves anodizing a product and giving different colors to specific areas. Although the process is complex and the cost is high, the two-color contrast can better reflect the product's high-end and unique appearance.

In general, aluminum profiles' processing performance is better than that of other materials, which allows them to meet the current market's customization needs and produce a variety of aluminum profile products. In addition, the surface treatment process of aluminum profiles is very rich, which greatly meets people's needs for construction and home decoration, making them widely used and deeply loved by the public.