Aluminum Alloy 6000 Series - Knowledge & Features

Updated: 21 May 2024

According to the aluminum alloy series, from pure aluminum with the lowest strength of 1000 series to aluminum-zinc alloy with the highest strength of 7000 series, different grades of deformed aluminum alloys have different compositions, heat treatment processes and corresponding processing forms, so they have different anodizing characteristics.

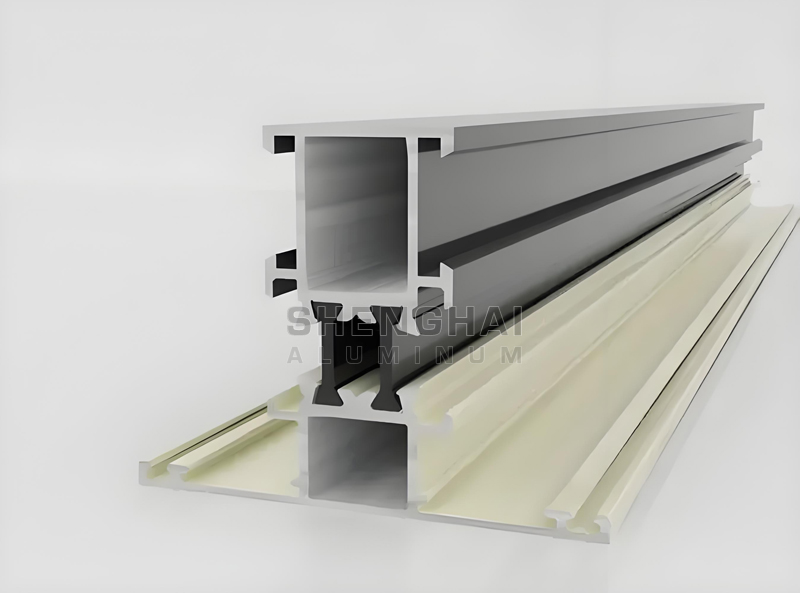

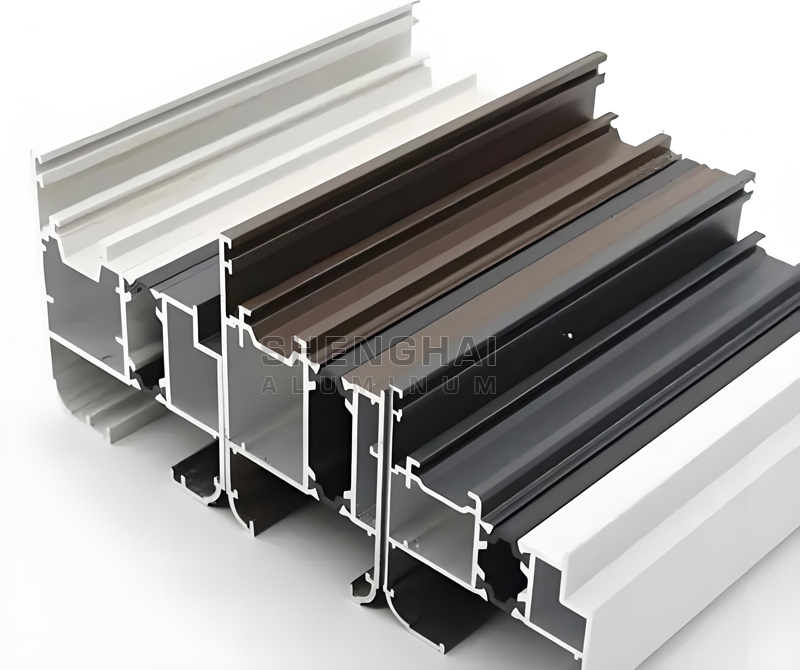

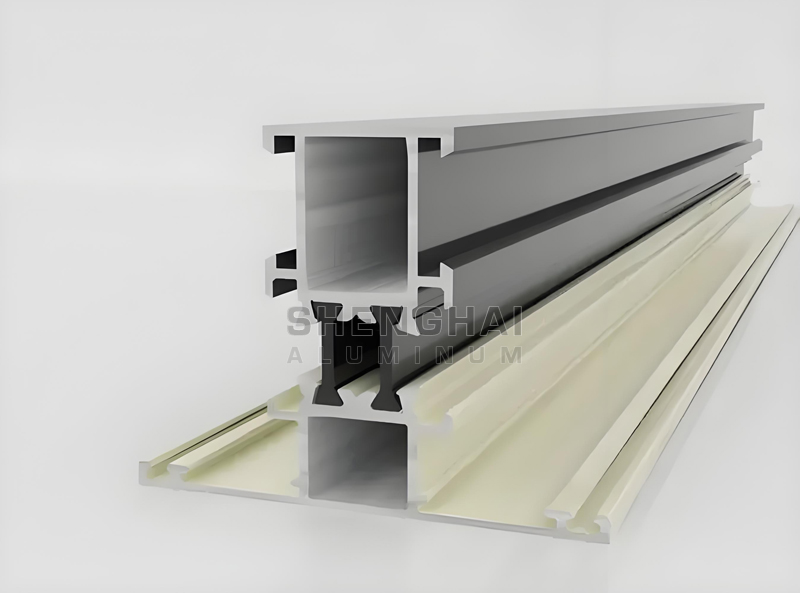

6000 series aluminum alloy, also known as "aluminum magnesium silicon alloy", is a heat-treated corrosion-resistant aluminum alloy with high strength, corrosion resistance, and good uniformity. It is a relatively popular product and is particularly important in engineering applications. , mainly used for extruded profiles. Taking the commonly used 6000 series aluminum alloys as an example, different types of aluminum alloys have different uses:

6005 extruded profiles and pipes, used for ladders, TV antennas, TV transmitters, etc.

6009 Automobile body panels.

6010 Thin sheet: automobile body.

6061 Tubes, rods and plates for battery covers, semiconductor equipment components, aviation fixtures, valve bodies, automobile parts, model car floors, bicycle accessories, ships, trams, furniture, mechanical parts, precision machining, etc.

6063 Construction profiles and extruded materials for vehicles, stands, furniture, fences, etc.

6066 Forgings and welded structural extrusion materials.

6068 is mainly used as refrigerated container floor plates, truck frame components, ship superstructure components, rail vehicle structural components, large truck structures and other mechanical structural components.

6070 Extruded materials and tubing for heavy-duty welded structures and the automotive industry.

6082 is suitable for manufacturing aircraft landing pads, boats, building components, bicycles, automobile parts, optical instruments, rail vehicle aluminum materials, electrical accessories, valves and valve parts.

6101 High-strength rods for buses, electrical conductors and heat dissipation equipment, high-strength electrical bus bars, rigid suspended conductive contact rails, various conductor materials, etc.

6106 is used for various pipes, wires and rods requiring corrosion resistance.

6151 is used for products that require good forgeability, high strength, and good corrosion resistance, such as die-forged crankshaft parts, machine parts, and production rolling rings.

6201 High strength conductive rods and wires.

6205 Thick plates, treads and high-impact extrusions.

6262 has good machinability and corrosion resistance. It is mostly used for extruded and cold-processed tubes, rods, shapes, and wire rods. It is used for threaded high-stress parts.

6351 is mostly used in extruded structural parts of highway transportation facilities and gas, oil, and water pipelines that require high strength.

6463 Construction and various appliance profiles and automobile decorative parts with bright surfaces after anodization.

6A02 Aircraft engine parts, forgings and die forgings with complex shapes.

The 6000 series aluminum alloy represents 6061, which is mainly magnesium and silicon. Therefore, it combines the advantages of the 4000 series and the 5000 series. 6061 is a cold-processed aluminum forged product suitable for applications requiring high corrosion and oxidation resistance. It also has good workability, easy coating, and good processability.

The 6000 series aluminum alloy represents 6061, which is mainly magnesium and silicon. Therefore, it combines the advantages of the 4000 series and the 5000 series. 6061 is a cold-processed aluminum forged product suitable for applications requiring high corrosion and oxidation resistance. It also has good workability, easy coating, and good processability.

6000 series aluminum alloy, also known as "aluminum magnesium silicon alloy", is a heat-treated corrosion-resistant aluminum alloy with high strength, corrosion resistance, and good uniformity. It is a relatively popular product and is particularly important in engineering applications. , mainly used for extruded profiles. Taking the commonly used 6000 series aluminum alloys as an example, different types of aluminum alloys have different uses:

6005 extruded profiles and pipes, used for ladders, TV antennas, TV transmitters, etc.

6009 Automobile body panels.

6010 Thin sheet: automobile body.

6061 Tubes, rods and plates for battery covers, semiconductor equipment components, aviation fixtures, valve bodies, automobile parts, model car floors, bicycle accessories, ships, trams, furniture, mechanical parts, precision machining, etc.

6063 Construction profiles and extruded materials for vehicles, stands, furniture, fences, etc.

6066 Forgings and welded structural extrusion materials.

6068 is mainly used as refrigerated container floor plates, truck frame components, ship superstructure components, rail vehicle structural components, large truck structures and other mechanical structural components.

6070 Extruded materials and tubing for heavy-duty welded structures and the automotive industry.

6082 is suitable for manufacturing aircraft landing pads, boats, building components, bicycles, automobile parts, optical instruments, rail vehicle aluminum materials, electrical accessories, valves and valve parts.

6101 High-strength rods for buses, electrical conductors and heat dissipation equipment, high-strength electrical bus bars, rigid suspended conductive contact rails, various conductor materials, etc.

6106 is used for various pipes, wires and rods requiring corrosion resistance.

6151 is used for products that require good forgeability, high strength, and good corrosion resistance, such as die-forged crankshaft parts, machine parts, and production rolling rings.

6201 High strength conductive rods and wires.

6205 Thick plates, treads and high-impact extrusions.

6262 has good machinability and corrosion resistance. It is mostly used for extruded and cold-processed tubes, rods, shapes, and wire rods. It is used for threaded high-stress parts.

6351 is mostly used in extruded structural parts of highway transportation facilities and gas, oil, and water pipelines that require high strength.

6463 Construction and various appliance profiles and automobile decorative parts with bright surfaces after anodization.

6A02 Aircraft engine parts, forgings and die forgings with complex shapes.