How To Produce Aluminium Profile By Aluminum Rod

Updated: 22 Apr 2024

Aluminium profiles are an engineering material widely used in various industries and fields. Their lightweight, high strength, corrosion resistance and recyclability make them the first choice for many applications. So, what is the process of aluminium profiles from raw materials to finished products?

Casting

Casting is the first step in aluminium profile manufacturing. At this stage, raw aluminum is added to the smelting furnace and melted using electricity or other forms of heat.

The molten aluminum liquid is refined through degassing and slag removal, which effectively removes impurities and gases in the melt and improves the purity of the aluminum liquid.

According to the specific alloy brand number that needs to be produced, the additional amount of various alloy components is calculated, various raw materials are reasonably matched, and these raw materials are added to the smelting furnace for melting.

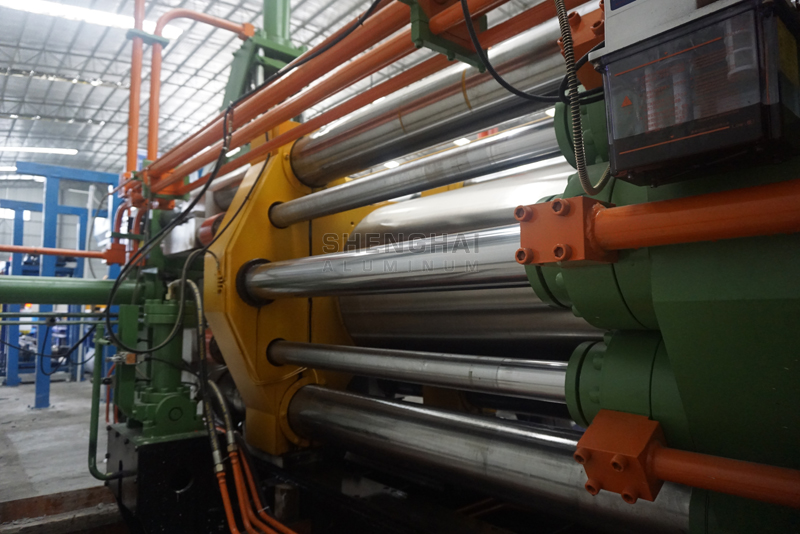

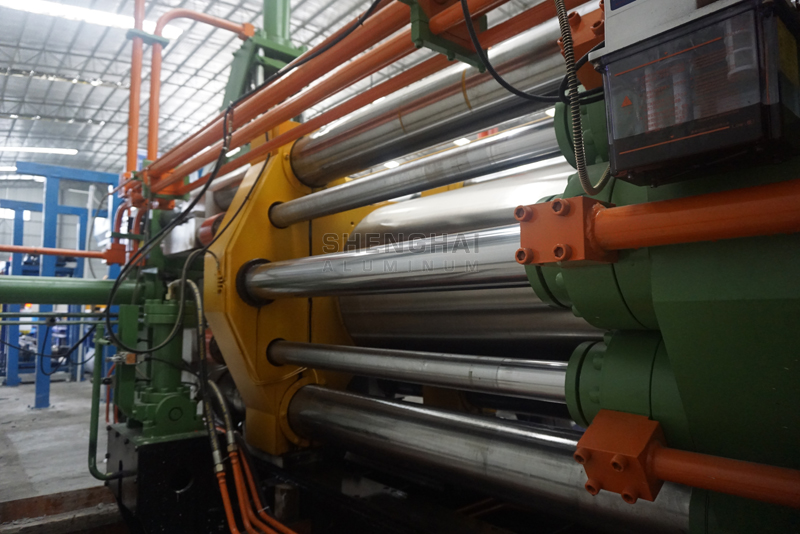

Extruded Aluminium Profile

Extrusion is one of the key steps in aluminium profile manufacturing. At this stage, a mold is designed and manufactured according to the cross-section design of the profile product, and the heated round cast rod is extruded from the mold.

During extrusion, an air-cooling quenching process and subsequent artificial aging process are also used to complete heat treatment strengthening. This step gives the aluminum profile the desired shape and dimensions and increases its strength and hardness.

Straightening

Straightening

The extruded aluminium profiles need to be straightened to ensure that the straightness of the aluminium profiles meets the standard. This step usually uses mechanical methods, such as straighteners or other specialized equipment, to correct the profile to achieve the required straightness.

Surface treatment

Surface treatment

Surface treatment is the final step in aluminium profile manufacturing. Generally, the surface of aluminum profiles is anodized silver-white, which is elegant, beautiful and corrosion-resistant.

Anodizing is an electrochemical process in which aluminum profiles are placed in an electrolyte solution and an oxide film is formed on the surface through electric current, thereby improving its corrosion resistance and aesthetics.

After anodizing treatment, a dense oxide film is formed on the surface of the aluminum profile, which has a good protective effect and can effectively prevent further oxidation and corrosion. In addition, other surface treatments, such as painting, spraying, etc., can be performed to meet different application needs.

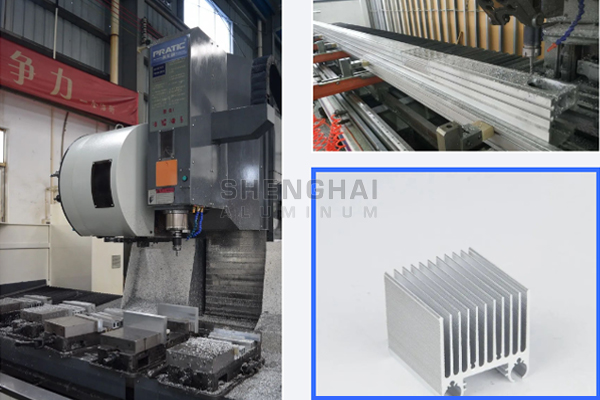

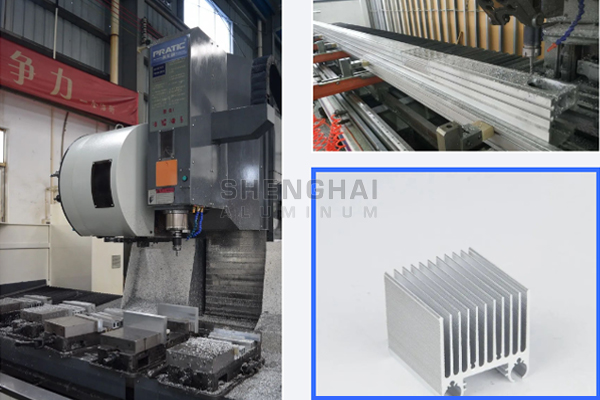

Deep Processing

After completing the above steps, the aluminum profile can be processed further. To meet different application needs, such as cutting, drilling, bending, etc..

These processing treatments can make aluminium profiles more suitable for the requirements of their application scenarios. In addition, some special processing, such as machining, polishing, etc., can also be performed to improve the accuracy and appearance quality of aluminum profiles.

Strict quality inspection is required during the manufacturing process, including appearance inspection, dimensional inspection, mechanical property inspection, etc. These tests can ensure that the quality and quality of aluminium profiles meet the requirements.

Strict quality inspection is required during the manufacturing process, including appearance inspection, dimensional inspection, mechanical property inspection, etc. These tests can ensure that the quality and quality of aluminium profiles meet the requirements.

Finally, aluminium profiles must be packaged to protect them from damage during transportation. Packaging can use various materials and methods, such as carton packaging, bubble packaging, etc.

Foshan Shenghai Aluminum can independently design and implement solutions. The company's products have many applications, including door and window profiles, edge trim profiles, LED profiles, aluminum t slot, wardrobe and kitchen cabinet profiles, etc. We have 500-1500 tons of extrusion lines, and also have anodizing, powder coating, electrophoresis and other supporting production lines. One-stop service to meet customers' production and processing needs for aluminium profiles.

Casting

Casting is the first step in aluminium profile manufacturing. At this stage, raw aluminum is added to the smelting furnace and melted using electricity or other forms of heat.

The molten aluminum liquid is refined through degassing and slag removal, which effectively removes impurities and gases in the melt and improves the purity of the aluminum liquid.

According to the specific alloy brand number that needs to be produced, the additional amount of various alloy components is calculated, various raw materials are reasonably matched, and these raw materials are added to the smelting furnace for melting.

Extruded Aluminium Profile

Extrusion is one of the key steps in aluminium profile manufacturing. At this stage, a mold is designed and manufactured according to the cross-section design of the profile product, and the heated round cast rod is extruded from the mold.

During extrusion, an air-cooling quenching process and subsequent artificial aging process are also used to complete heat treatment strengthening. This step gives the aluminum profile the desired shape and dimensions and increases its strength and hardness.

The extruded aluminium profiles need to be straightened to ensure that the straightness of the aluminium profiles meets the standard. This step usually uses mechanical methods, such as straighteners or other specialized equipment, to correct the profile to achieve the required straightness.

Surface treatment is the final step in aluminium profile manufacturing. Generally, the surface of aluminum profiles is anodized silver-white, which is elegant, beautiful and corrosion-resistant.

Anodizing is an electrochemical process in which aluminum profiles are placed in an electrolyte solution and an oxide film is formed on the surface through electric current, thereby improving its corrosion resistance and aesthetics.

After anodizing treatment, a dense oxide film is formed on the surface of the aluminum profile, which has a good protective effect and can effectively prevent further oxidation and corrosion. In addition, other surface treatments, such as painting, spraying, etc., can be performed to meet different application needs.

Deep Processing

After completing the above steps, the aluminum profile can be processed further. To meet different application needs, such as cutting, drilling, bending, etc..

These processing treatments can make aluminium profiles more suitable for the requirements of their application scenarios. In addition, some special processing, such as machining, polishing, etc., can also be performed to improve the accuracy and appearance quality of aluminum profiles.

Finally, aluminium profiles must be packaged to protect them from damage during transportation. Packaging can use various materials and methods, such as carton packaging, bubble packaging, etc.

Foshan Shenghai Aluminum can independently design and implement solutions. The company's products have many applications, including door and window profiles, edge trim profiles, LED profiles, aluminum t slot, wardrobe and kitchen cabinet profiles, etc. We have 500-1500 tons of extrusion lines, and also have anodizing, powder coating, electrophoresis and other supporting production lines. One-stop service to meet customers' production and processing needs for aluminium profiles.